“Aluminum latches have gained substantial prominence across numerous sectors thanks to their robust nature, exceptional light weight, and remarkable resistance against corrosion. These adaptable components are frequently employed in doors, windows, cabinets, and even outdoor furnishings. Their extensive utilization has catalyzed a heightened demand for superior quality aluminum latches capable of enduring severe environmental conditions. In this discourse, we shall explore the four pivotal prerequisites for aluminum latches, scrutinizing their design, material selection, installation, and upkeep.”

Design Considerations for Aluminum Latches

The physical configuration of aluminum latches significantly influences their efficiency and practicality. Here are some vital design aspects:

1. Security: The prime objective of a latch is to fortify a door or window. Crafting latches with robust locking systems guarantees they can withstand deliberate intrusion attempts.

2. User- Friendliness: A proficiently designed aluminum latch should be user-friendly, even for those with diminished hand dexterity. This encompasses attributes such as seamless functioning and minimal exertion required to engage or disengage the latch.

3. Compatibility: Latches ought to be harmonious with diverse door and window materials, like timber, steel, or aluminum. This guarantees their utility across myriad applications.

4. Weather Resilience: Aluminum latches should be architected to endure severe weather conditions, encompassing extreme temperature fluctuations, humidity, and precipitation.

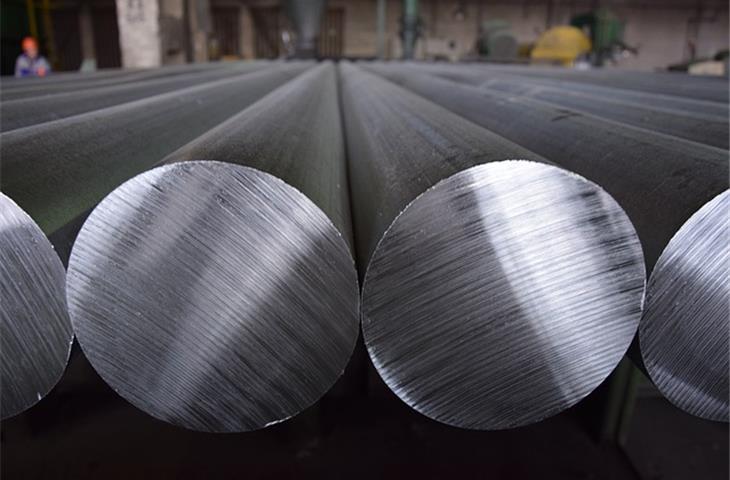

Material Selection for Aluminum Latches

The selection of materials for aluminum latches substantially influences their durability and efficacy. Here are some critical variables to contemplate:

1. Aluminum Alloy: Opting for the appropriate aluminum alloy ensures the latch is both lightweight and resilient to corrosion and deformation.

2. Surface Treatment: Incorporating a suitable surface treatment, such as anodizing or powder coating, can augment the latch’s resistance towards environmental elements and prolong its service life.

3. Hardware: The hardware components, such as nuts and screws, should be fabricated from rust-resistant materials, akin to stainless steel, to circumvent wear and tear.

Installation of Aluminum Latches

Efficient installation remains paramount for assuring maximum performance of aluminum latches. Here are some installation contemplations:

1. Measuring: Reliable measuring of the door or window dimensions is indispensable for achieving a fitting latch.

2. Drilling Holes: Drilling holes for the latch and its hardware components should be executed meticulously to prevent damage to the door or window frame.

3. Assembly: Constructing the latch and its hardware components should be carried out diligently to guarantee a secure and efficient installation.

Maintenance of Aluminum Latches

Routine maintenance is crucial for extending the lifespan of aluminum latches. Here are some maintenance guidelines:

1. Cleaning: Frequently cleansing the latch with a soft cloth and mild detergent can aid in removing dirt and grime that might accumulate over time.

2. Lubrication: Infusing a lubricant, such as petroleum jelly or lithium-based lubricant, can facilitate smooth operation and deter corrosion.

3. Inspection: Conducting periodic inspections of the latch for indications of wear and tear can assist in identifying potential issues prior to them escalating into significant complications.

In summation, aluminum latches have evolved into an integral component of various industries owing to their versatility and robustness. By concentrating on design, material selection, installation, and maintenance, manufacturers can fabricate top-tier aluminum latches that cater to the needs of varied applications. As the demand for aluminum latches continues to escalate, it is imperative for manufacturers to prioritize these four key prerequisites to assure customer gratification and enduring products.